Establishing Verification Environment in Shibuya for AI Data Centers Compatible with Cutting-edge GPU Servers

―Large-capacity power supply and high-performance cooling capability will be used for conducting verifications in cooperation with partner companies―

KDDI Corporation

Tokyo, February 25, 2025―In April 2025, KDDI will establish a verification environment for AI data center technologies including cooling technologies and power supply solutions for cutting-edge GPU servers, at the Telehouse Tokyo Shibuya. This verification environment will support the operations of the AI data center that KDDI plans to build at the former site of SHARP's Sakai factory (hereinafter referred to as "Sakai AI Data Center") [![]() 1] in FY2025. In addition, KDDI will collaborate with partner companies that develop and manufacture server components, including GPUs, to conduct joint verifications.

1] in FY2025. In addition, KDDI will collaborate with partner companies that develop and manufacture server components, including GPUs, to conduct joint verifications.

High-performance GPUs consumes a significant amount of power during operation, requiring large-capacity power supply facilities. As the server performance increases, the amount of heat generated also rises. The adoption of liquid cooling technologies that can cool down servers more efficiently is essential when operating an AI data center, in addition to the improvement of cooling efficiency of the air-cooling technologies that are used for conventional data centers.

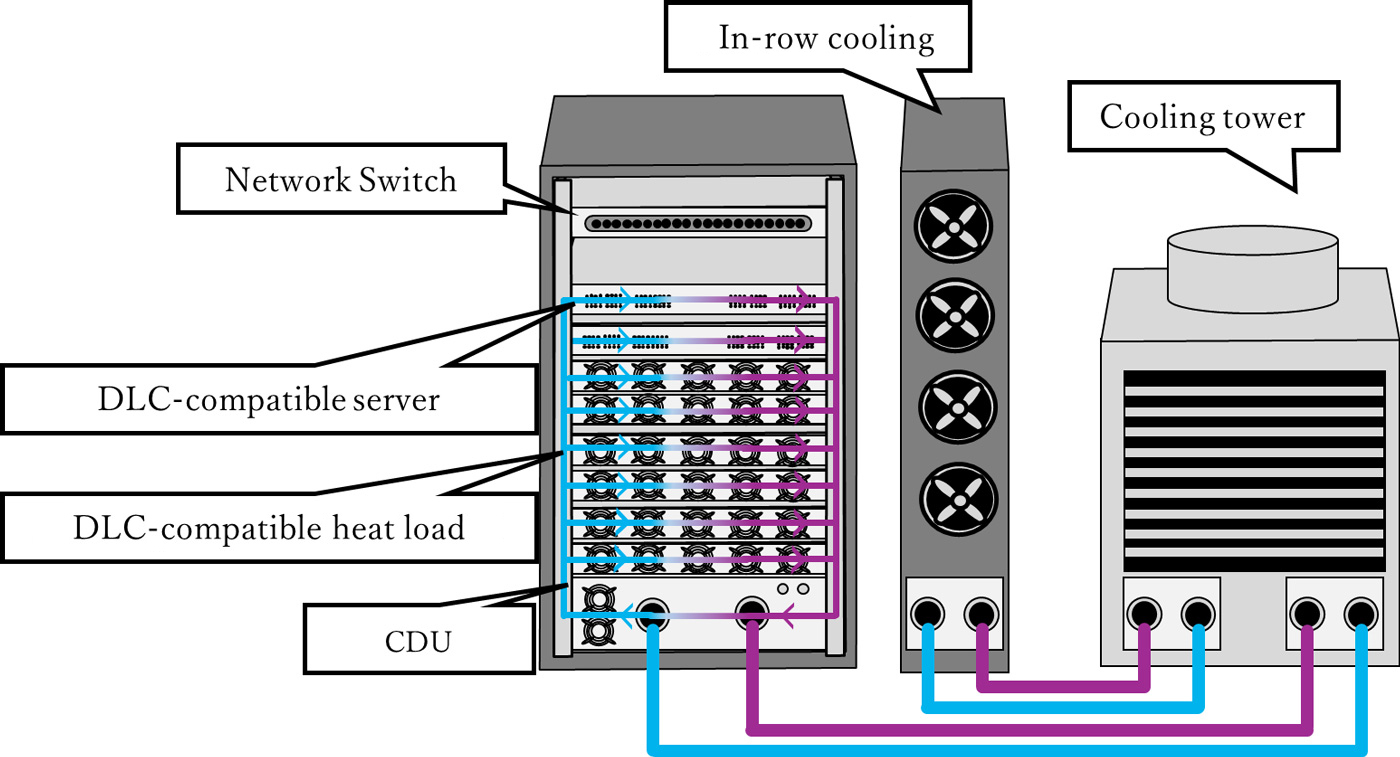

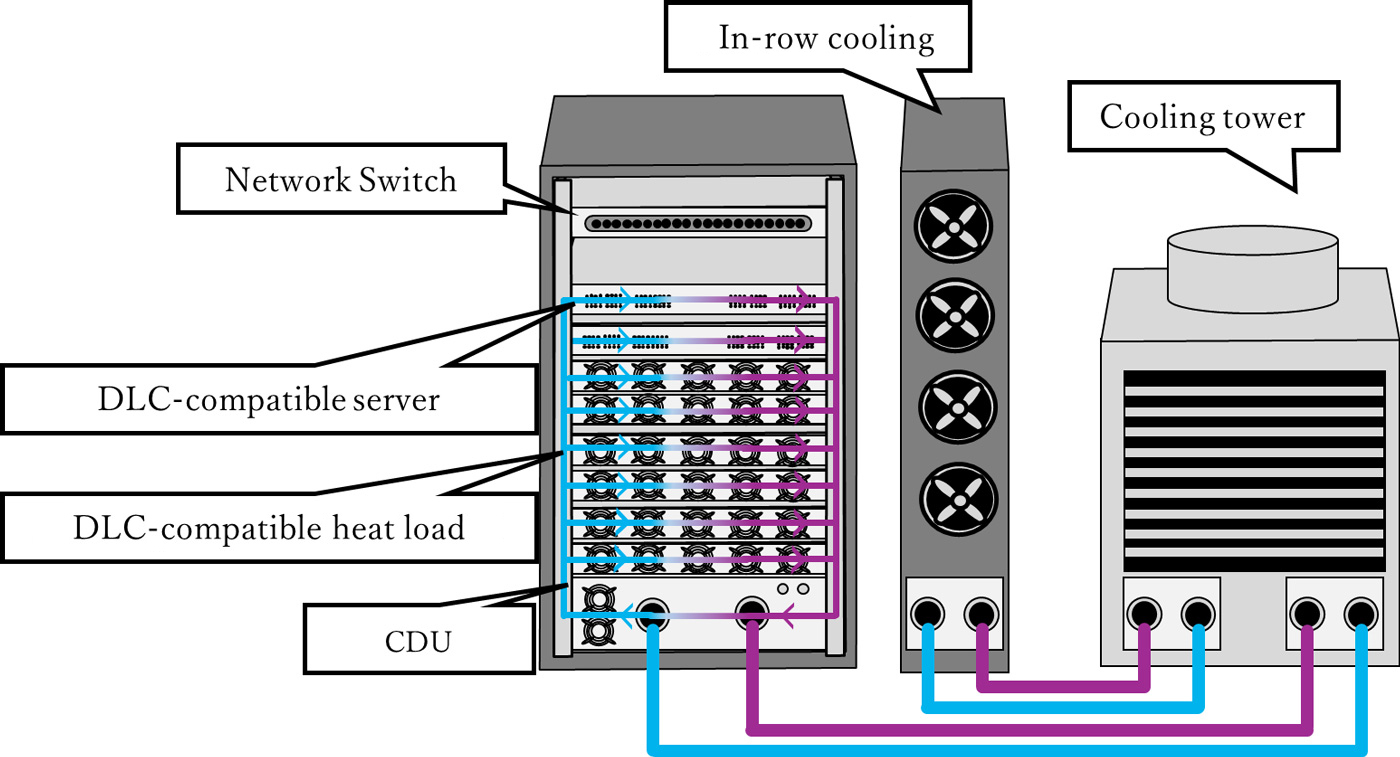

The verification environment will combine servers compatible with the Direct Liquid Cooling (DLC) method (in which cold liquid is sent directly into a server) and heat loads that simulate GPUs. The facility will have a maximum power supply capacity of 300 kVA and a maximum cooling capability of 300 kW, enabling verifications intended for NVIDIA GB200 NVL72, which is a cutting-edge GPU to be installed in the Sakai AI Data Center.

Moreover, environment sensors for measuring power sources and temperatures and liquid leak detection sensors will be installed to enable data collection and monitoring during operation.

KDDI will use the verification environment to collaborate with partner companies on the creation of new cooling technologies for data centers and the development and technological verification of highly efficient power supply facilities. KDDI will continue to cooperate with partner companies across various industries and sectors to validate new technologies and drive their commercialization.

This item will be exhibited at MWC Barcelona 2025, the world's largest mobile-related trade show held in Spain from March 3rd to 6th, 2025. For more details, please visit the KDDI MWC Barcelona 2025 special website

■Background

- KDDI is planning to install NVIDIA GB200 NVL72, a cutting-edge GPU, in the Sakai AI Data Center. As the performance of semiconductor chips has improved and the number of transistors contained has increased, the amount of heat generated per rack has increased more than tenfold compared to conventional chips. It is therefore essential for the data center to support DLC that can remove heat from servers efficiently with low power consumption.

- As the use of AI increases and spreads in the future, it is expected that demand for DLC-compatible AI data centers will grow and the need for installing DLC-compatible facilities in currently operating data centers that use air cooling technologies will also increase.

- To fulfill those needs as soon as possible, KDDI will retrofit the existing Telehouse Tokyo Shibuya to support DLC and build a verification environment that can be used for establishing and improving the facility design and operation method optimum to future commercialization, including the cooperation with manufacturers that have cutting-edge cooling technologies in technological verifications and countermeasures against liquid leaks.

■About the verification environment

1. Features

- (1) Heat load tests intended for GPU can be conducted

The combination of a DLC-compatible server and heat load enables verification intended for GPU to be conducted. For example, verification intended for NVIDIA GB200 NVL72 with 100 kW or more per rack can be conducted.

- (2) Data of the operation of a liquid-cooled server can be collected via environment sensors

The verification environment will be equipped with sensors for measuring power, temperatures, and so on. Those sensors enable data relating to the operation of a liquid-cooled server to be constantly collected and analyzed.

- (3) Safety devices linked to liquid leak detection sensors will be installed

As countermeasures against liquid leaks and other failures in a commercial environment, the verification environment will be equipped with liquid leak detection sensors and safety devices such as emergency cutoff valves that are automatically activated by the sensors. Verifications can be conducted without affecting the surrounding environment even when a failure such as a liquid leak occurs.

2. Details

3. Companies cooperating in building the verification environment and conducting verifications

Super Micro Computer, Inc.

NIDEC CORPORATION

Shinohara Electric Co., Ltd.

- *The information contained in the articles is current at the time of publication.

Products, service fees, service content and specifications, contact information, and other details are subject to change without notice.

Downloads